The Solid State Relay (Static Relay) Overview (on photo: Basler Electric BE1-27 Solid State Protective Relay, Over/Under Voltage)

History of Relay

The static relay is the next generation relay after electromechanical type.The Solid Static relays was first introduced in 1960’s. The term ‘static’ implies that the relay has no moving mechanical parts in it.

Compared to the Electromechanical Relay, the Solid Static relay has longer life-span, decreased noise when operates and faster respond speed.

However, it is not as robust as the Electromechanical Relay.

Static relays were manufactured as semiconductor devices which incorporate transistors, ICs, capacitors, small microprocessors etc.

The static relays have been designed to replace almost all the functions which were being achieved earlier by electromechanical relays.

Measuring principles

The working principle of the Solid Static relays is similar to that of the Electromechanical Relay which means the Solid Static relays can perform tasks that the Electromechanical Relay can perform.

The Solid Static relays use analogue electronic devices instead of magnetic coils and mechanical components to create the relay characteristics. The measurement is carried out by static circuits consisting of comparators, level detectors, filter etc while in a conventional electromagnetic relay it is done by comparing operating torque (or force) with restraining torque (or force). The relaying quantity such as voltage/current is rectified and measured.

In a solid state relay, the incoming voltage and current waveforms are monitored by analog circuits, not recorded or digitized. The analog values are compared to settings made by the user via potentiometers in the relay, and in some case, taps on transformers.

In some solid state relays, a simple microprocessor does some of the relay logic, but the logic is fixed and simple.

For instance, in some time over current solid state relays, the incoming AC current is first converted into a small signal AC value, and then the AC is fed into a rectifier and filter that converts the AC to a DC value proportionate to the AC waveform. An op-amp and comparator is used to create a DC that rises when a trip point is reached. Then a relatively simple microprocessor does a slow speed A/D conversion of the DC signal, integrates the results to create the time-over current curve response, and trips when the integration rises above a set point.

Though this relay has a microprocessor, it lacks the attributes of a digital/numeric relay, and hence the term “microprocessor relay” is not a clear term.

Function of Relay

Early versions used discrete devices such as transistors and diodes in conjunction with resistors, capacitors, inductors, etc., but advances in electronics enabled the use of linear and digital integrated circuits in later versions for signal processing and implementation of logic functions.

While basic circuits may be common to a number of relays, the packaging was still essentially restricted to a single protection function per case, while complex functions required several cases of hardware suitably interconnected.

Basler Electric BE1-27 Solid State Protective Relay, Over/Under Voltage

User programming was restricted to the basic functions of adjustment of relay characteristic curves.

Therefore it can be viewed in simple terms as an analogue electronic replacement for electromechanical relays, with some additional flexibility in settings and some saving in space requirements.

In some cases, relay burden is reduced, making for reduced CT/VT output requirements. In a static relay there is no armature or other moving element and response is developed by electronic, magnetic or other components without mechanical motion.

The performance of static relay is better than electromagnetic relays as they are fast acting and accuracy of measurement is better than electromagnetic relay.

The constraint in static relay is limited function/features.

In the last decade, some microprocessors were introduced in this relay to achieve the functions like:

- Fuse failure features

- Self check feature

- Dead Pole detection and

- Carrier aided protection features

Operation of Relay

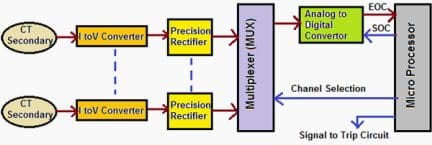

The essential components of static relays are shown in figure below. The output of CT and PT are not suitable for static components so they are brought down to suitable level by auxiliary CT and PT. Then auxiliary CT output is given to rectifier.

Rectifier rectifies the relaying quantity i.e., the output from a CT or PT or a Transducer.

Solid state relay - Operation

The rectified output is supplied to a measuring unit comprising of comparators, level detectors, filters, logic circuits.

The output is actuated when the dynamic input (i.e., the relaying quantity) attains the threshold value. This output of the measuring unit is amplified by amplifier and fed to the output unit device, which is usually an electromagnetic one.

The output unit energizes the trip coil only when relay operates.

Advantages of Solid State Relay

- Static Relay burden is less than Electromagnetic type of relays. Hence error is less.

- Low Weight

- Required Less Space which results in panel space saving.

- Arc less switching

- No acoustical noise.

- Multi-function integration.

- Fast response.

- Long life (High Reliability): more than 109 operations

- High Range of Setting compared to electromechanical Relay

- More Accurate compared to electromechanical Relay

- Low Electromagnetic Interference.

- Less power consumption.

- Shock and vibration resistant

- No contact bounce

- Microprocessor compatible.

- Isolation of Voltage

No moving parts: There are no moving parts to wear out or arcing contacts to deteriorate that are often the primary cause of failure with an Electro Mechanical Relay.

No mechanical contact bounce or arcing: A solid-state relay doesn’t depend on mechanical forces or moving contacts for its operation but performs electronically. Thus, timing is very accurate even for currents as low as the pickup value. There is no mechanical contact bounce or arcing, and reset times are extremely short.

Low input signal levels: Ideal for Telecommunication or microprocessor control industries. Solid state relays are fast becoming the better choice in many applications, especially throughout the telecommunication and microprocessor control industries.

Cost Issues: In the past, there has been a rather large gap between the price of an electromechanical relay and the price of a solid state relay. With continual advancement in manufacturing technology, this gap has been reduced dramatically making the advantages of solid state technology accessible to a growing number of design engineers.

Limitations of static relays

- Auxiliary voltage requirement for Relay Operation.

- Static relays are sensitive to voltage transients which are caused by operation of breaker and isolator in the primary circuit of CTs and PTs.

- Serious over voltage is also caused by breaking of control circuit, relay contacts etc. Such voltage spikes of small duration can damage the semiconductor components and also cause mal operation of relays.

- Temperature dependence of static relays: The characteristics of semiconductor devices are affected by ambient temperature.

- Highly sophisticated isolation and filter circuits are required to be built into the relay design to take care of electromagnetic interference and transient switching disturbances in the power system.

- Highly reliable power supply circuits are required.

- Effect of environmental conditions like humidity, high ambient temperature, dust accumulation on PCB leading to tracking.

- The component failure.

- Non availability of fault data.

- Characteristic variations with passage of time.

References

- Handbook of Switchgear –Bhel

- Digital/Numerical Relays -T.S.M. Rao